The aim of improving a value chain is to achieve the highest business value in the shortest possible time, consistently, sustainably and with a high level of quality.

The "Value stream Value Stream Lean" is one of the (5) Lean principles, and for many reasons, it's a good idea to understand your organization's value chains and processes.

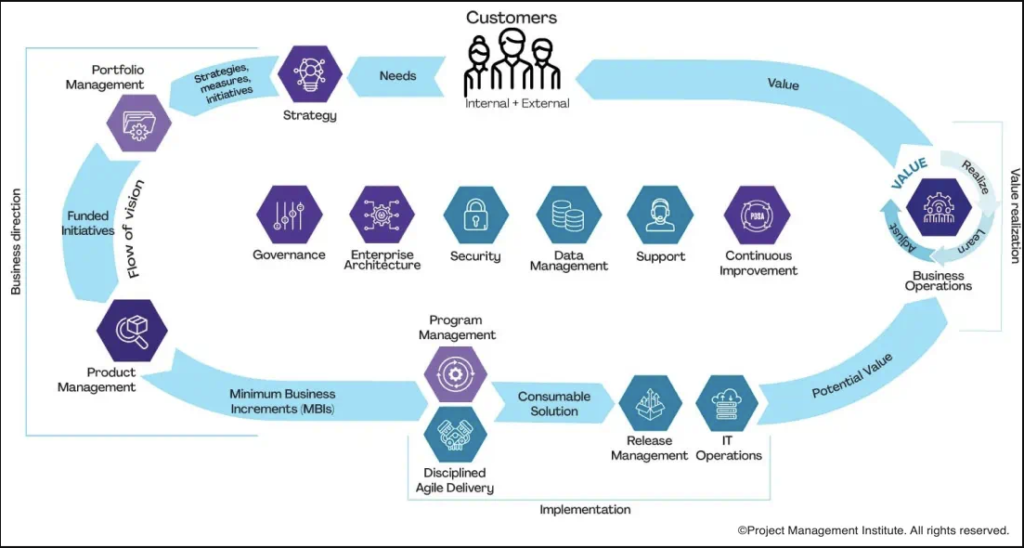

To increase organizational agility, we need to look at all our value chains ("Value Streams"), not just at the team level. This allows us to see how each component of a system is interrelated (systems thinking), and reminds us that we are trying to shorten the time between concept and consumption of the solution ("Concept to cash").

To find out more, read our article L'LEAN AGILE THINKING.

To achieve these goals, many companies are turning to advanced methodologies and management tools, and one of these powerful methods is Value Stream Mapping (VSM).

What is a value chain (Value Stream)?

The value chain is the set of actions implemented to bring added value to a customer, from the initial request to the realization of value by the customer. The value chain is the work itself, not the people who do it.

*** A value chain always begins and ends with a customer. ***

The problem with current organizational structures is that no one is focused on the whole job. To remedy this lack of focus on the overall workflow, we need to broaden our vision of agility to include the whole organization.

Value chains must be managed by flow, with horizontal accountability (left to right) rather than by function (silos).

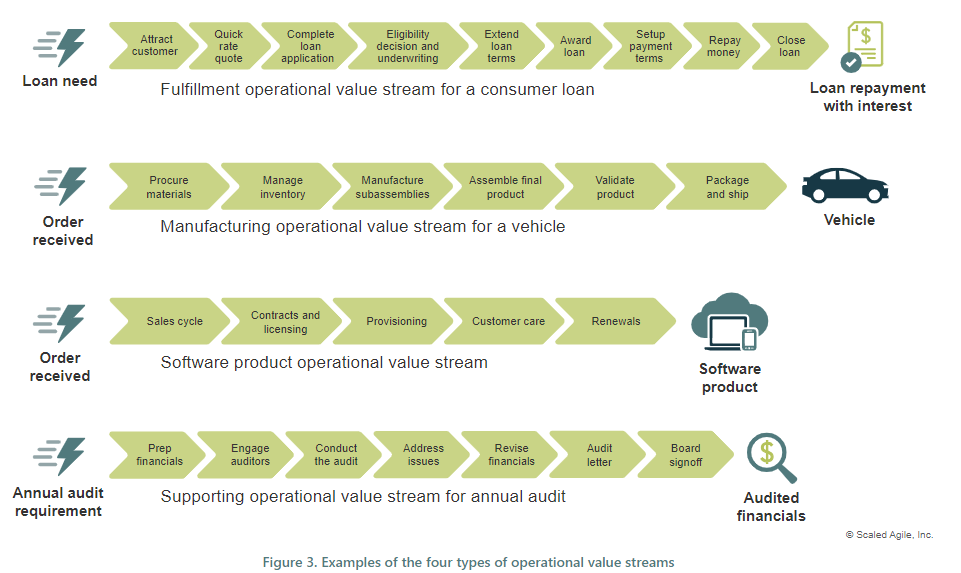

The three types of value chains (Value Stream)

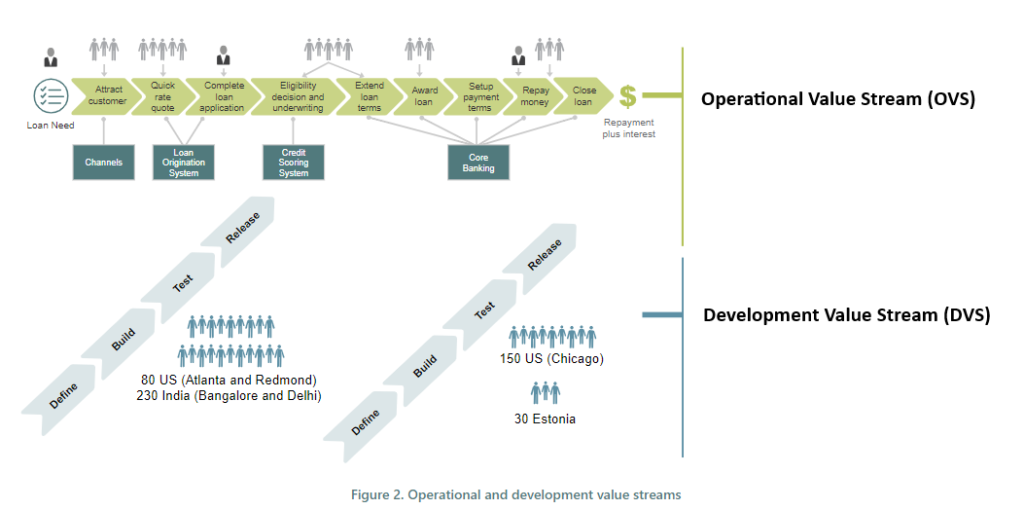

- Development Value Stream (DVS)

- The sequence of activities required to develop and support a solution (product) used by the operational value chain (OVS).

- Ex. : Define, design (develop), test, put into production.

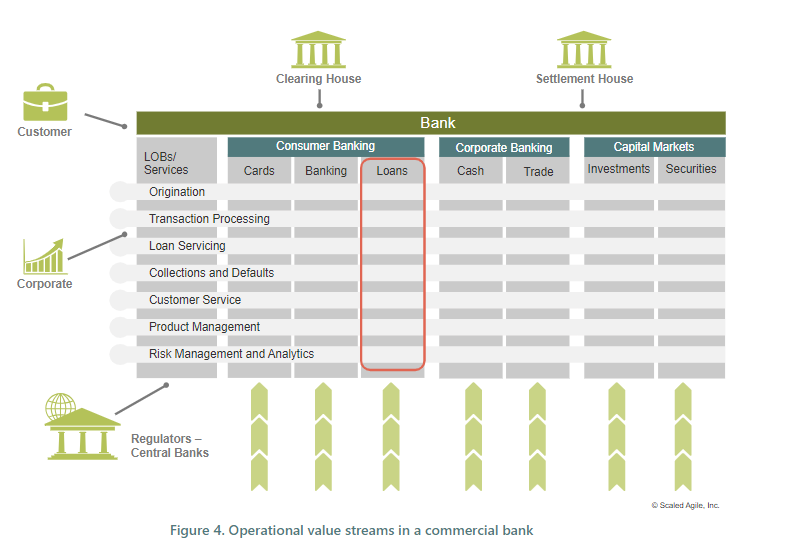

- Operational Value Stream (OVS)

- The sequence of activities required to deliver a product or service to a customer.

- Ex. : The steps involved in manufacturing a product, the steps involved in fulfilling an order, the steps involved in admitting & treating a patient, the steps involved in granting a mortgage, etc.

- Value Stream support

- Work that supports the day-to-day activities of an organization.

- Ex. HR, finance, procurement, etc.

Value chain types (value stream) in pictures

Scaled Agile, Inc.

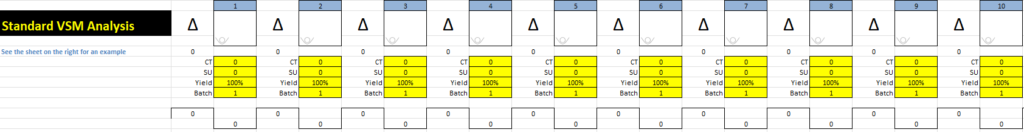

What is process mapping (Value Stream Mapping) ?

Value Stream Mapping is a management technique rooted in the Lean philosophy.

It is a methodology for visualizing, analyzing and optimizing business processes to eliminate waste, improve efficiency and create more value for the customer. VSM uses detailed maps to represent the flow of materials, information and actions throughout the entire process.

Source : https://www.pmi.org/disciplined-agile/process/value-streams

Benefits of value chain mapping (Value Stream Mapping)

- Cost reduction: By eliminating waste, companies can save money.

- Quality improvement: By identifying and eliminating sources of error, the quality of products or services improves.

- Reduced lead times: More efficient processes mean faster delivery to customers.

- Better communication: VSM promotes internal communication by clearly visualizing processes.

- Customer satisfaction: By offering better value, customers are more satisfied.

Does value chain mapping (Value Stream Mapping) is an agile practice?

Value stream mapping is a common practice in the agile method. It enables us to see where the flow of value delivery is slowing down, and reveals opportunities to create better alignment between teams.

Focus on resource utilization ... One of the threats to efficiency...

One of the biggest threats to effective working is the focus on resource utilization. The way we generally manage people is to make sure they're always 100% busy. This focus on high utilization almost always results in reduced throughput.

When we impose more work on ourselves, it leads to delays and we discover mistakes we've made. This creates waste. In many cases, the more work we "push", the more we fall behind for reasons such as :

- Waiting

- Run several tasks in parallel (multitasking)

- Workflow delays (e.g. work pushed beyond capacity, poor value-creation structure, interruptions, lack of visibility).

- Retravail (Rework)

- Lack of predictability

To learn more about a team's capacity vs. demand for work, consult this excellent article!

Systems thinking

Systems thinking is a holistic approach to analysis that focuses on how the constituent elements of a system interact together, and how systems function over time and in the context of a larger system.

Systems thinking will be used to examine the organizational structure and determine how to improve the value chain.

Conclusion

Value Stream Mapping (Value Stream Mapping) is a powerful tool for improving efficiency, reducing costs and satisfying customers. By adopting this method, your organization will be able to visualize workflows and their dependencies at all levels.

Not to mention more efficient processes and the elimination of waste between different value chains. If you're looking to optimize your operations, the Value Stream Mapping could definitely be the key to your success, especially if you're planning to experiment with Lean Portfolio Management

We hope this article has provided you with a useful introduction to Value Stream Mapping". Value Stream Mapping ". Don't hesitate to contact us if you need help mapping value chains within your company.

About the author

With over 20 years of experience management Information Technology, Éric Auger helps companies accelerate their value delivery and optimize their organizational performance. IT consultant specializing in project management, Lean Six Sigma Green Belt Practitioner, Kanban management expert and Agility coachI combine strategy, tactics and operations to maximize your competitiveness in the digital age.

Passionate about digital transformationI work with organizations to optimize their value flowguaranteeing sustainable competitive advantage. I also like share my expertise and help professionals strengthen their skills in project management and agility.

Follow me for practical advice and proven strategies to make your projects a success.